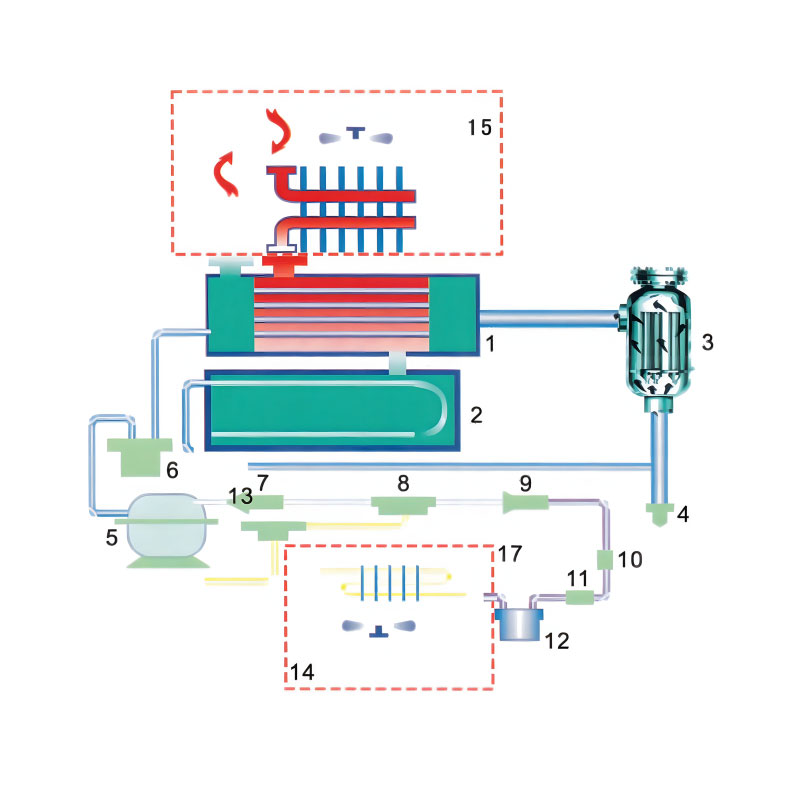

Compressed Air will firstly enter the pre-cooling unit (15) for preliminary cooling, then enter the heat regenerator (1), exchanging heat with the returned finished air, which reduce the temperature of the compressed air. The condensates will be discharged out of the machine. Later, the compressed air enters the evaporator (2), exchanging heat with the coolant to further reduce the temperature of the compressed air, thus achieving the designed dew point.

The compressed air is cooled step by step through pre-cooling unit (18 or 19), heat regenerator (1) and evaporator (2), after that, the vapour in the air will be condensed into water drops. The liquid water will be separated through gas-liquid separator (3).

The dry and cooled air, through the gas-liquid separator (3), will be passed to another process in the heat regenerator (1), heated up before leaving the dryer, so that reduce the Relative Humidity in the air.

This early dryers adopts mature technology from USA HANKISON and combines with our own practical operation features in China, keeping it running stable and efficient with scientific design. "HANFILTER" refrigerated dryer won several national patent with its unique technology, stable running, low dew point and high stability. Moreover, HANFILTER is also one of the writer for preparation of the GB National industry standards - just like ISO8973. "General Purpose Refrigerated Compressed Air Dryers" and "General Purpose Controllers for Desiccant Compressed Air Dryers", and thus becoming the one of the few domestic manufacturers with top advanced technology.

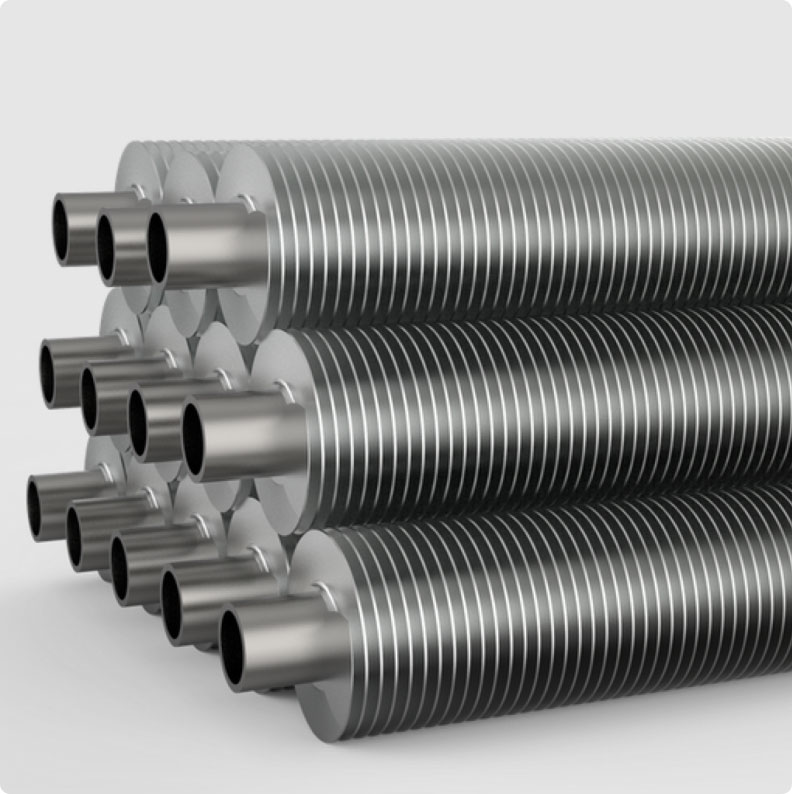

High quality and efficient thread tubes or light tubes ensure a professional thermal conduction index, while the reverse flow heating in the heat exchanger will be better energy-efficient and stable than the typical flow type.

The utilization of patented technology, the condensate from the refrigerated dryer are separated in full and discharged outside the machine via reliable auto-drains, significantly reducing the malfunctions during the refrigerated dryer operation, improving the quality of the air source, allowing HANFILTER's refrigerated dryer to work stably and effectively under different operational conditions. Therefore, Hanfilter's unique technology is national patent protected.

(Patent No.: ZL200720057808.9)

To ensure the efficient and stable running as well as energy saving of the refrigerated dryer under different conditions, HANFILTER refrigerated dryers are classified, as per the customers' needs and actual conditions, as: high inlet temperature air-cooling type, high inlet temperature water-cooling type, regular inlet temperature air-cooling and water-cooling types.

Seamless Durable components Environment Durable components Integration