Each of our high-quality adsorption dryers can achieve extremely low pressure dew points under difficult ambient conditions – even with large volume flows. It combines with the practical operation features to create more stable and reliable dryers with smart design and manufacturing, raising the customer satisfactions. "HANFILTER" desiccant dryer won several national patent with its state-of-art technology, stable running, excellent dew point performance and high stability. "General Purpose Refrigerated Compressed Air Dryers" and "General Purpose Desiccant Compressed Air Dryers", Quality must never be just a promise. We practise quality at Hanfilter. In our production, each assembly cell has its own specially adapted quality control.

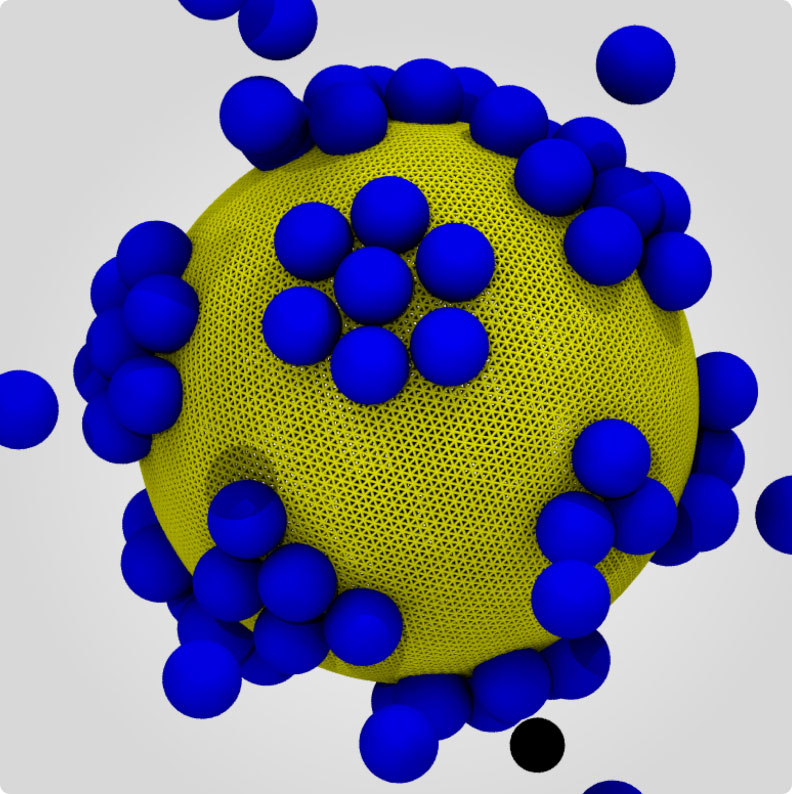

1. Unique desiccant ball with diameter of 3.0mm, gaining bigger activated surface area, higher absorptive ability and anti- crushing strength, longer life.

2. 30% extra desiccant volume to enlarge the working hours of the dryers, ensure a stable and excellent pressure dew point performance.

3. Excellent desiccant tower with the height-diameter ratio basic on scientific and accurate calculate.It takes less pressure drop and energy saving.

There are countless details that we pay attention to during product development: all Hanfilter products are designed according to economic efficiency, reliability and durability. All core products are developed and manufactured in-house with the kind of attention to detail you notice.The result: proven economical, reliable and maintenance-friendly solutions. With our broad standard portfolio, we already cover all compressed air purity classes according to ISO 8573-1. We treat condensate completely, from discharge to treatment. Economical and safe.

Use excellent performance and reliable butterfly valve and solenoid valve, with lifecycle exceeding 1 million open-close times.

Seamless Durable components Environment Durable components Integration